Production Cost How To Estimate The Unit Cost

Product Cost Formula Calculator Examples With Excel Template The company purchases $1,000 worth of new materials to make product x. now, the total inventory value is: $1,500 $1,000 = $2,500. after manufacturing product x, let’s say the company’s ending inventory (inventory left over) is $500. this means, the cost of direct materials is: $2,500 – $500 = $2,000. The concept can also be used at the level of an entire factory, to derive the average cost of every unit produced within it. the formula is as follows: (total direct materials costs total direct labor costs total factory overhead costs) ÷ number of units produced. = unit product cost. while the preceding description may make it appear that.

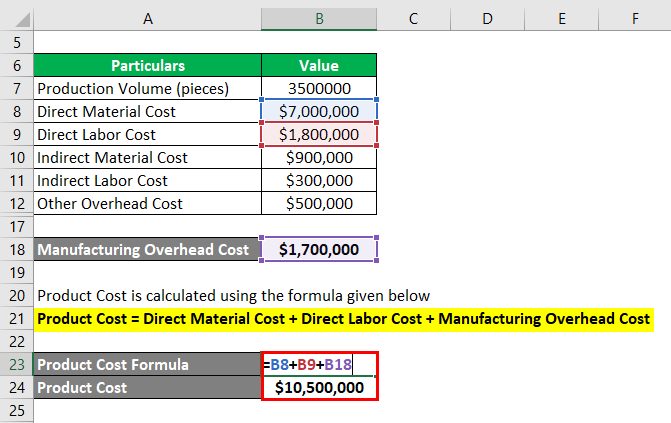

Planned Unit Cost Versus Actual Unit Cost Comparison Chart Excel Template An Help the business of finished chairs to determine the cost of production. use the given data for the calculation of production cost. calculation of direct labor using below formula can be done as follows, direct labor = wages of production workers benefits of the production workers. = $40,000 $3,000. The following equation is used to calculate a unit product cost. c = ( dm dl o ) u c = (dm dl o) u. where c is the unit product cost. dm is the direct material costs. dl is the direct labor costs. o is the factory overhead costs. u is the total units produced. to calculate a unit product cost, sum the material, labor, and overhead. Total product costs can be determined by adding together the total direct materials and labor costs as well as the total manufacturing overhead costs. data like the cost of production per unit or. For example, if 5,000 units will cost a company $10,000 to manufacture, then the unit product cost or price per unit, is $2.00 each. in practice, however, things are often more complex.

Comments are closed.