How To Estimate The Manufacturing Cost For A New Electronic Product Case Stu

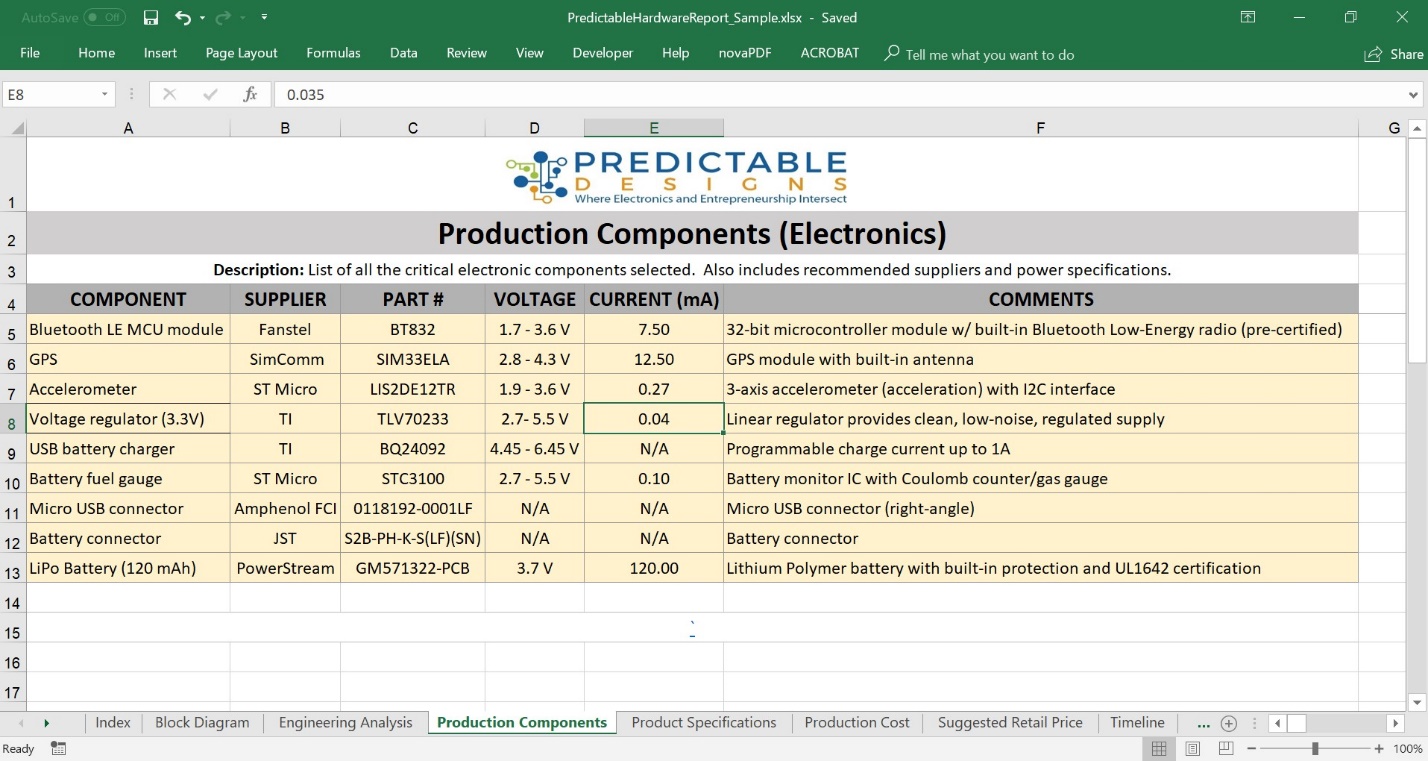

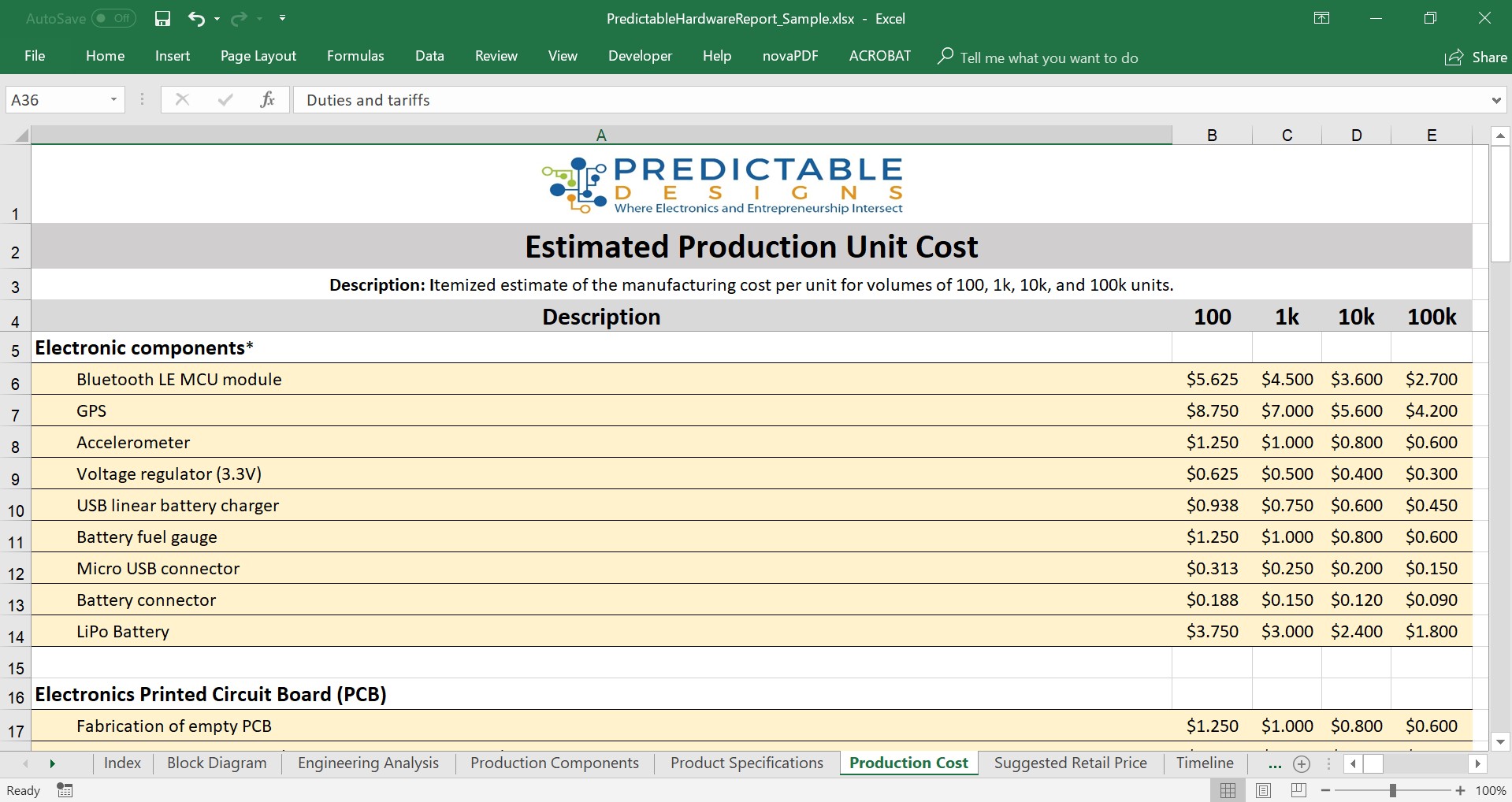

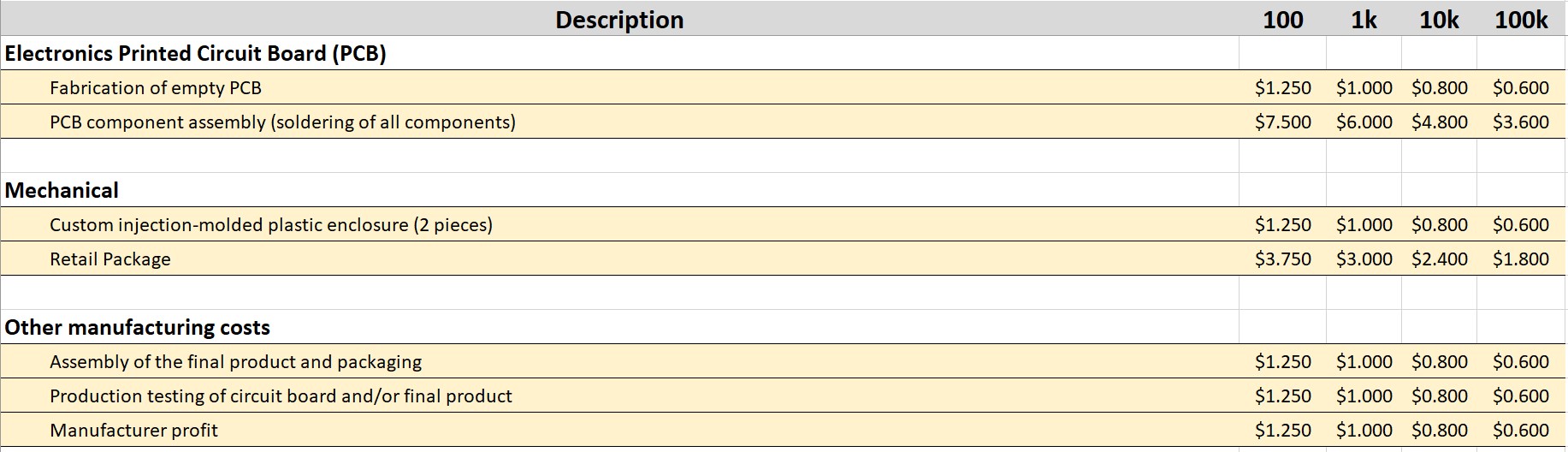

How To Estimate The Manufacturing Cost For A New Electronic Product To be able to compete, you’ll need to base the price of your product on your high volume landed production cost. in my example, i’m using the price at 100k units to set the retail price. the total landed cost for the hypothetical ble gps tracking device was $24.09 at 100k units. Every manufacturing operation must employ a basic cost estimation process to ensure profitability. this often involves tallying up expected input costs based on recent market prices and then adding markup for packaging, shipping, and profit. if the estimate exceeds current market prices, then production is not viable.

How To Estimate The Manufacturing Cost For A New Electronic Product Management. today, however, identifying costs in manufacturing is far more complex. it involves an in depth evaluation of every product cost element and its relationship to characteristics like form, fit, and function, alongside the process requirements for manufacturing, sourcing, and distribution. You can expect to spend at least several thousand dollars to develop the 3d models for the enclosure. if appearance and ergonomics are critical for your product then the cost to design the 3d model will be higher. nearly all electronic hardware products require a case or enclosure. The company purchases $1,000 worth of new materials to make product x. now, the total inventory value is: $1,500 $1,000 = $2,500. after manufacturing product x, let’s say the company’s ending inventory (inventory left over) is $500. this means, the cost of direct materials is: $2,500 – $500 = $2,000. Quick review of production costs. there are many different factors that affect how much it costs to manufacture an electronic product. the total manufacturing cost formula is: variable costs fixed costs = total cost of production. it can be difficult to calculate total manufacturing cost before speaking with your manufacturer.

How To Estimate The Manufacturing Cost For A New Electronic Product The company purchases $1,000 worth of new materials to make product x. now, the total inventory value is: $1,500 $1,000 = $2,500. after manufacturing product x, let’s say the company’s ending inventory (inventory left over) is $500. this means, the cost of direct materials is: $2,500 – $500 = $2,000. Quick review of production costs. there are many different factors that affect how much it costs to manufacture an electronic product. the total manufacturing cost formula is: variable costs fixed costs = total cost of production. it can be difficult to calculate total manufacturing cost before speaking with your manufacturer. You have two options for shipping your product from china to the us – by air or by sea. shipping your product by air is the quickest method but it is also the most expensive. these costs can cut into your profit margins significantly. the heavier your product is, the more expensive it is to ship by air. To calculate the total manufacturing cost for a given period, you can use the following formula: total manufacturing cost = direct materials direct labor manufacturing overhead. 1. direct materials calculation. to determine direct materials cost, sum up the cost of all materials used in production during the specified period.

How To Calculate Manufacturing Cost The Tech Edvocate You have two options for shipping your product from china to the us – by air or by sea. shipping your product by air is the quickest method but it is also the most expensive. these costs can cut into your profit margins significantly. the heavier your product is, the more expensive it is to ship by air. To calculate the total manufacturing cost for a given period, you can use the following formula: total manufacturing cost = direct materials direct labor manufacturing overhead. 1. direct materials calculation. to determine direct materials cost, sum up the cost of all materials used in production during the specified period.

Comments are closed.