Water Cooled Condensers Facts That Will Blow Your Mind Industrial Manufacturing Bl

Water Cooled Condensers Facts That Will Blow Your Mind This type of condenser can be housed indoors. a water cooled system typically lasts years longer, assuming maintenance is not neglected. it has higher heat transfer rate. it consumes far less overall energy, which can lead to savings on energy costs and consumption. it does not require any external power. Water cooled condensers #3: coaxial tube in tube. overview: coaxial tube in tube is the third type of condenser in a water cooled chiller. it earns its name because the tubes are coiled around the same axis. excellent anti fouling characteristics make these high performance and compact heat exchangers stand out from other condenser types.

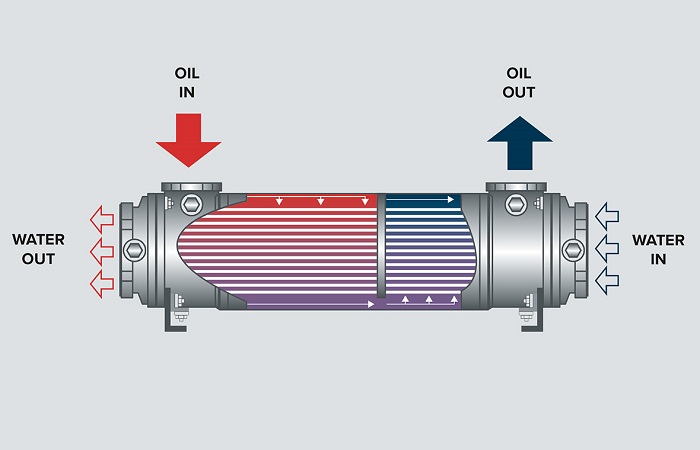

Water Cooled Condensers Facts That Will Blow Your Mind 1. refrigerant vapor: the refrigerant, heated during the cooling process, enters the condenser as a hot, high pressure gas. 2. heat exchange: inside the condenser, the refrigerant vapor passes over coils or tubes filled with water. the water absorbs the heat from the refrigerant, causing the refrigerant to cool and condense into a liquid. Water cooled condensers are heat exchangers used in various industries to transfer heat from a system or process to water. these condensers are commonly employed in refrigeration, air conditioning, power plants, and other applications where it is necessary to remove heat efficiently. in the context of refrigeration and air conditioning systems. Cons: lower efficiency: air cooled condensers are generally less efficient than water cooled ones, especially in high temperature environments. this can impact the overall performance of the system. higher operating temperatures: air cooled systems tend to operate at higher condensing temperatures, which can reduce the efficiency of the entire. 1) air cooled condenser: this type of water cooled condenser uses an outside source for cooling, like an air conditioning unit or an evaporative cooler. these are typically installed in large buildings with many square feet and are not recommended for small buildings such as homes or offices. 2) evaporative cooling: this type of water cooled.

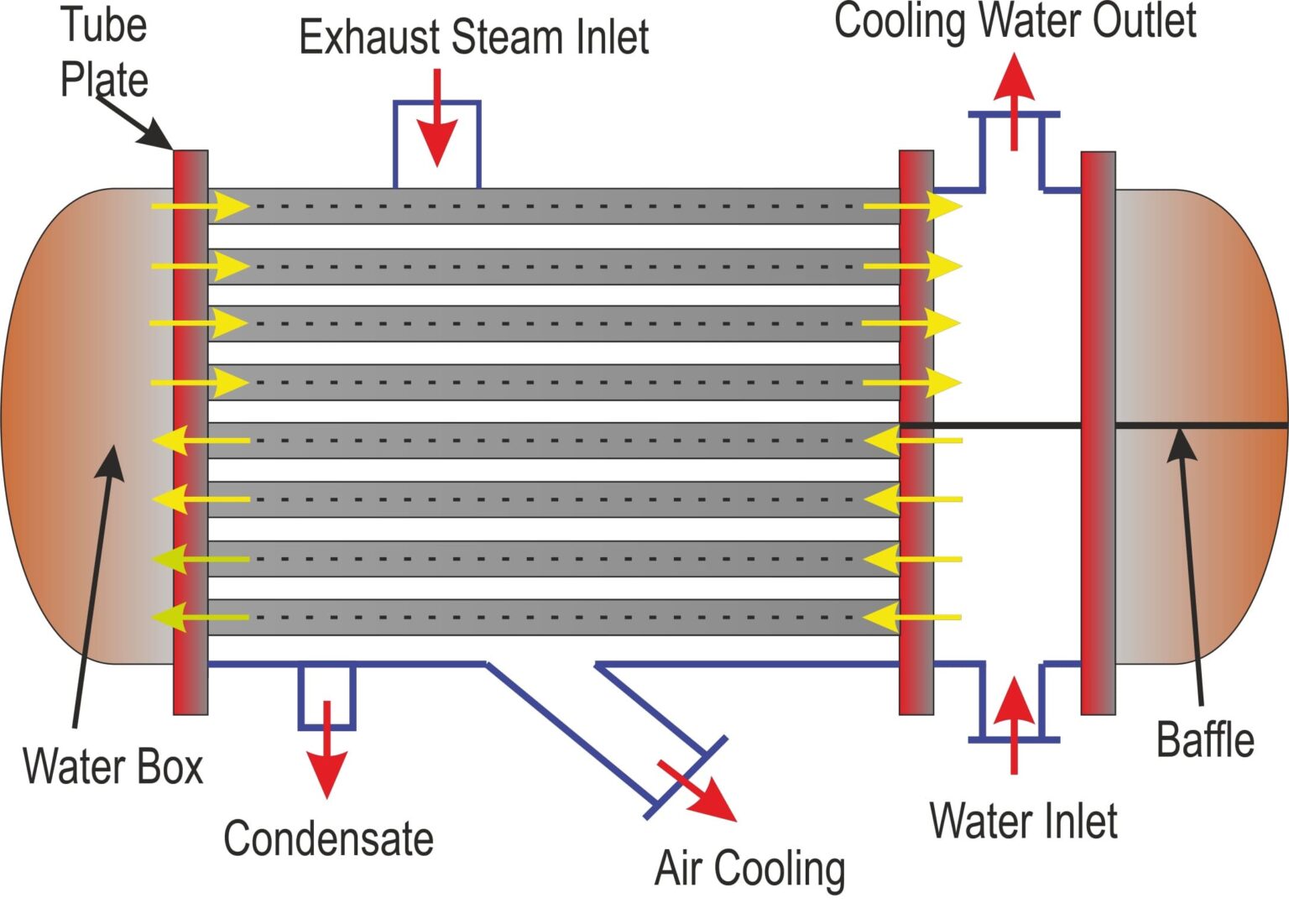

Water Cooled Condensers Facts That Will Blow Your Mind Cons: lower efficiency: air cooled condensers are generally less efficient than water cooled ones, especially in high temperature environments. this can impact the overall performance of the system. higher operating temperatures: air cooled systems tend to operate at higher condensing temperatures, which can reduce the efficiency of the entire. 1) air cooled condenser: this type of water cooled condenser uses an outside source for cooling, like an air conditioning unit or an evaporative cooler. these are typically installed in large buildings with many square feet and are not recommended for small buildings such as homes or offices. 2) evaporative cooling: this type of water cooled. Holtec condensers, including steam surface condensers and bypass condensers, are custom engineered for power plants ranging in output from 10mw to 1500mw. holtec’s water cooled condensers are designed for a variety of configurations, such as cylindrical, inverted “u,” rectangular, axial exhaust, down exhaust, single or multiple pressure. The water cooled condenser is the only type utilized when the distance between the compressor and the heat rejection site is too long to pump the refrigerant vapor with an acceptable pressure drop. in practice, water cooled condensers are built in sizes from 0.5 to 10,000 tr capacities [31]. these condensers are used mainly used in heat pumps.

Water Cooled Condenser Diagram Holtec condensers, including steam surface condensers and bypass condensers, are custom engineered for power plants ranging in output from 10mw to 1500mw. holtec’s water cooled condensers are designed for a variety of configurations, such as cylindrical, inverted “u,” rectangular, axial exhaust, down exhaust, single or multiple pressure. The water cooled condenser is the only type utilized when the distance between the compressor and the heat rejection site is too long to pump the refrigerant vapor with an acceptable pressure drop. in practice, water cooled condensers are built in sizes from 0.5 to 10,000 tr capacities [31]. these condensers are used mainly used in heat pumps.

The Three Types Of Water Cooled Condensers Drake Refrigeration Inc

Comments are closed.