Part 1 Full Duramax Engine Rebuild Very Detailed

Part 1 Full Duramax Engine Rebuild Very Detailed Youtube Having trouble figuring out how to rebuild your duramax engine? this short series of videos should help!. Now that the crank is in and good to go, time to install the rods and the rest of the components onto the block and start putting everything back together! s.

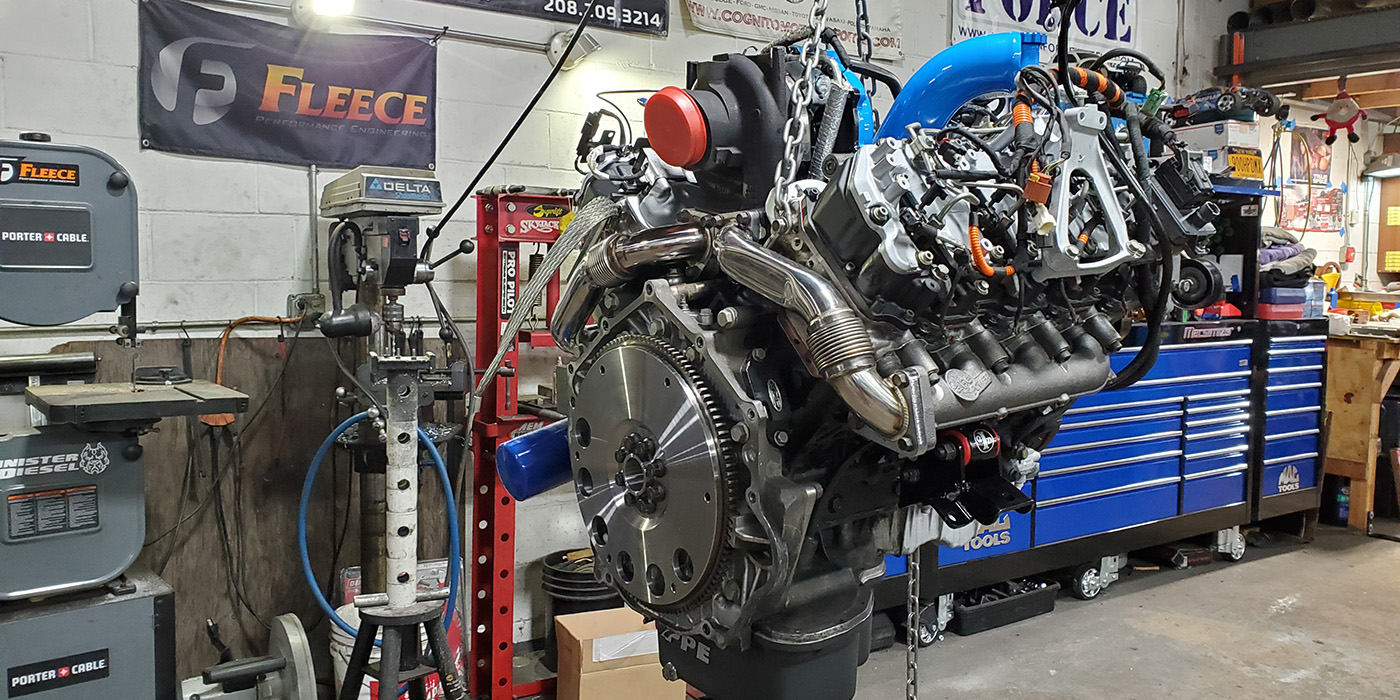

Lb7 Duramax Engine Rebuild Part 1 Engine Removal Youtube Cylinder head m12 bolts (angular tightening method): 1st step 37 ft lb; 2nd step 59 ft lb; 3rd step 60 degrees; 4th step 60 degrees cylinder head m8 bolts: 18 ft lb. drive belt tensioner pulley. 2005 duramax lly engine rebuild. wassup everyone im gana post up some of my motor rebuild picts. let me know what you think! it all started when i realized the dealer sold me a truck with bad head gaskets. they went out of business because 6 people were suing them. fast forward two years i desided its was time to fix it. Part 1 of 3 about rebuilding a lb7 duramax motor from the bottom up. this episode is specifically about removing the engine from the truck. thanks for tuning. A new 650,000 sq. ft. engine plant was built near the former 6.5l diesel engine plant, and many of the employees were able to transfer to the new joint venture. the totally new engine design was a 6.6l, 90 degree, direct injection, overhead valve, four valve per cylinder, turbo charged diesel v8 with aluminum high swirl cylinder heads.

Rebuilt Lb7 Duramax Engine Part 1 of 3 about rebuilding a lb7 duramax motor from the bottom up. this episode is specifically about removing the engine from the truck. thanks for tuning. A new 650,000 sq. ft. engine plant was built near the former 6.5l diesel engine plant, and many of the employees were able to transfer to the new joint venture. the totally new engine design was a 6.6l, 90 degree, direct injection, overhead valve, four valve per cylinder, turbo charged diesel v8 with aluminum high swirl cylinder heads. 1) install motor without front clip turn over and run for less than 1 min allow oil system to pressurize. turn off inspect for any leaks misses. pull if necessary otherwise, complete reassembly. 2) finish install fill coolant fluids. 3) startup do quick inspection for any leaks. <1min. Next, the cylinders were bored and honed, the mains were line honed, and finally the head mounting surface was decked. this all ensured the block was perfectly square and ready to run for another.

Duramax Rebuild Youtube 1) install motor without front clip turn over and run for less than 1 min allow oil system to pressurize. turn off inspect for any leaks misses. pull if necessary otherwise, complete reassembly. 2) finish install fill coolant fluids. 3) startup do quick inspection for any leaks. <1min. Next, the cylinders were bored and honed, the mains were line honed, and finally the head mounting surface was decked. this all ensured the block was perfectly square and ready to run for another.

Comments are closed.