How To Generate Solid Bodies With Synera Lesson 05

Using Joints To Connect Line And Solid Bodies Ansys Mechanical Tutorial For Beginner You Learn how to generate geometries like curves, surfaces and solids by using a closed curve to create a boundary surface and extruding it to generate a solid b. 19 dec 15 10:40. after reading a lot of posts regarding this issue, i still don't get it how to generate a solid from a surface. i will explain my steps (it's about nx 10): 1 import the step data. 2 heal geometry. 3 reopen the healed geoemtry and extract surfaces. 4 sew with tight tolerance (0.001) no problem in sewing operation.

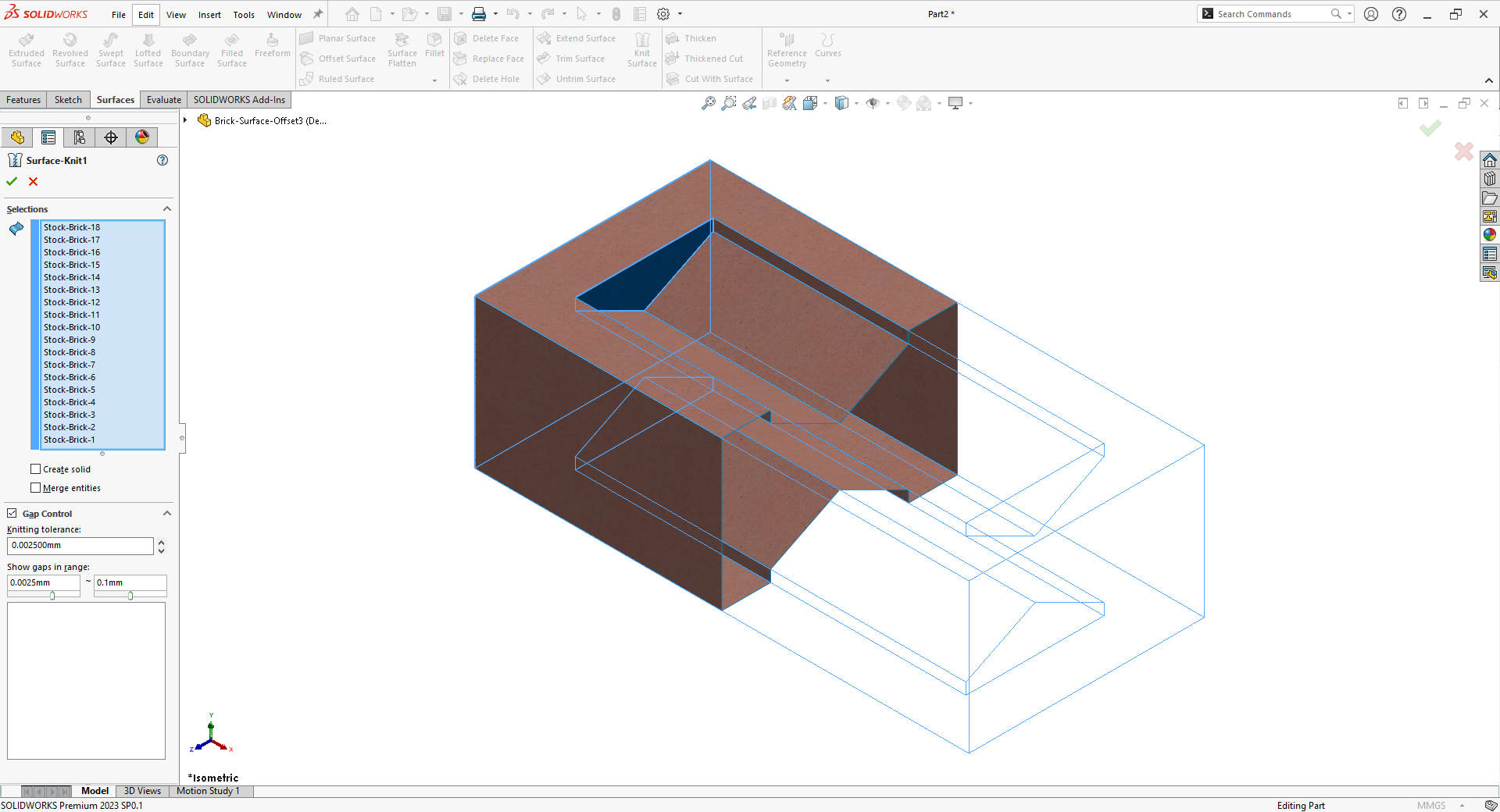

Surface Modelling How To Convert Surfaces To Solid Bodies In Solidwor Merge all components (.prt) of your assembly (.asm) to one single solid body, while the (.asm) file is opened in session and the window is active. then save the file as a step file. when you open right now this step file in any cad application, you will see in the model tree "one" imported solid feature only. a second way: save your assemly as. Extrude the sketch and use the intersect option to keep only the material that intersects the sketch and the solid body; expand the solid bodies folder in the browser and turn on the visibility of the both solid bodies; use the combine tool and choose the first solid as the base and the second as the toolbody, and be sure to select the cut. This often has advantages but, in this case, we need one complete surface to fill its volume and create a solid. to merge these surfaces into one solid body, we use the knit surface command found on the surfaces tab. if you don’t see your surfaces tab, right click on the command manager > tabs and enable surfaces. Select trim surface available in the surfaces toolbar or go to insert > surface > trim. to create a solid body, you must select mutual under trim type in property manager. under selections, select all the surfaces that will represent the final solid body. with keep selections selected, select faces that form the enclosed volume of your solid.

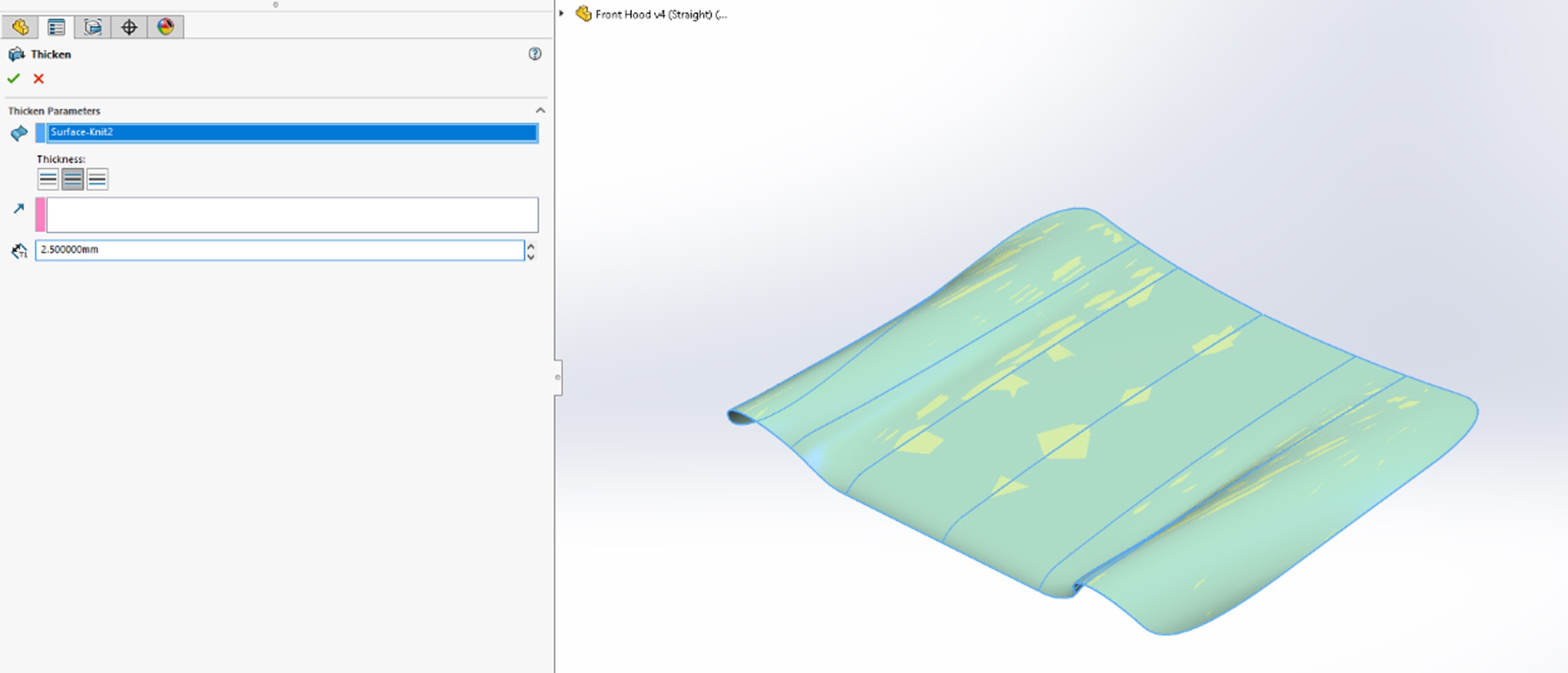

Surface Modelling How To Convert Surfaces To Solid Bodies In Solidwor This often has advantages but, in this case, we need one complete surface to fill its volume and create a solid. to merge these surfaces into one solid body, we use the knit surface command found on the surfaces tab. if you don’t see your surfaces tab, right click on the command manager > tabs and enable surfaces. Select trim surface available in the surfaces toolbar or go to insert > surface > trim. to create a solid body, you must select mutual under trim type in property manager. under selections, select all the surfaces that will represent the final solid body. with keep selections selected, select faces that form the enclosed volume of your solid. Method 1: patch and stitch. the first and most common method involves using surface tools such as ‘patch’ to fill in the end of the surface. following this, we ‘stitch’ the patched surfaces together to create a closed, watertight volume. autodesk fusion automatically converts a closed volume into a solid body when using the stitch tool. If you have a lot of surfaces you can knit (insert > surface >knit) them together then thicken will apply a thickness to all the surfaces at once. on the other hand if you have surfaces that create a closed body you just knit all the surfaces together to make it a solid, as long as the surface edges are within a nice tight tolerance and there.

Solid Body Turning Into Surface Bodies In Ansys Fluid Flow Fluent Method 1: patch and stitch. the first and most common method involves using surface tools such as ‘patch’ to fill in the end of the surface. following this, we ‘stitch’ the patched surfaces together to create a closed, watertight volume. autodesk fusion automatically converts a closed volume into a solid body when using the stitch tool. If you have a lot of surfaces you can knit (insert > surface >knit) them together then thicken will apply a thickness to all the surfaces at once. on the other hand if you have surfaces that create a closed body you just knit all the surfaces together to make it a solid, as long as the surface edges are within a nice tight tolerance and there.

Comments are closed.