Data Drives Future Of Smart Manufacturing

Data Drives Future Of Smart Manufacturing Youtube Using a sensor network, intel collects data on its fan filter units, brings that data directly to the cloud where it runs analytics that predict when units might go down. “instead of having an unscheduled break, intel can now schedule maintenance during planned downtime,” wells said. as a result, intel has been able to improve uptime by 97%. The ml ai growth has been enabled by massive data storage capacity and increased compute performance, leading to projections for the semiconductor industry to reach over $1 trillion in annual revenue by 2030, with about 50% of the industry’s growth related to genai 2. fig. 1: mckinsey & company on genai driving semiconductor industry growth.

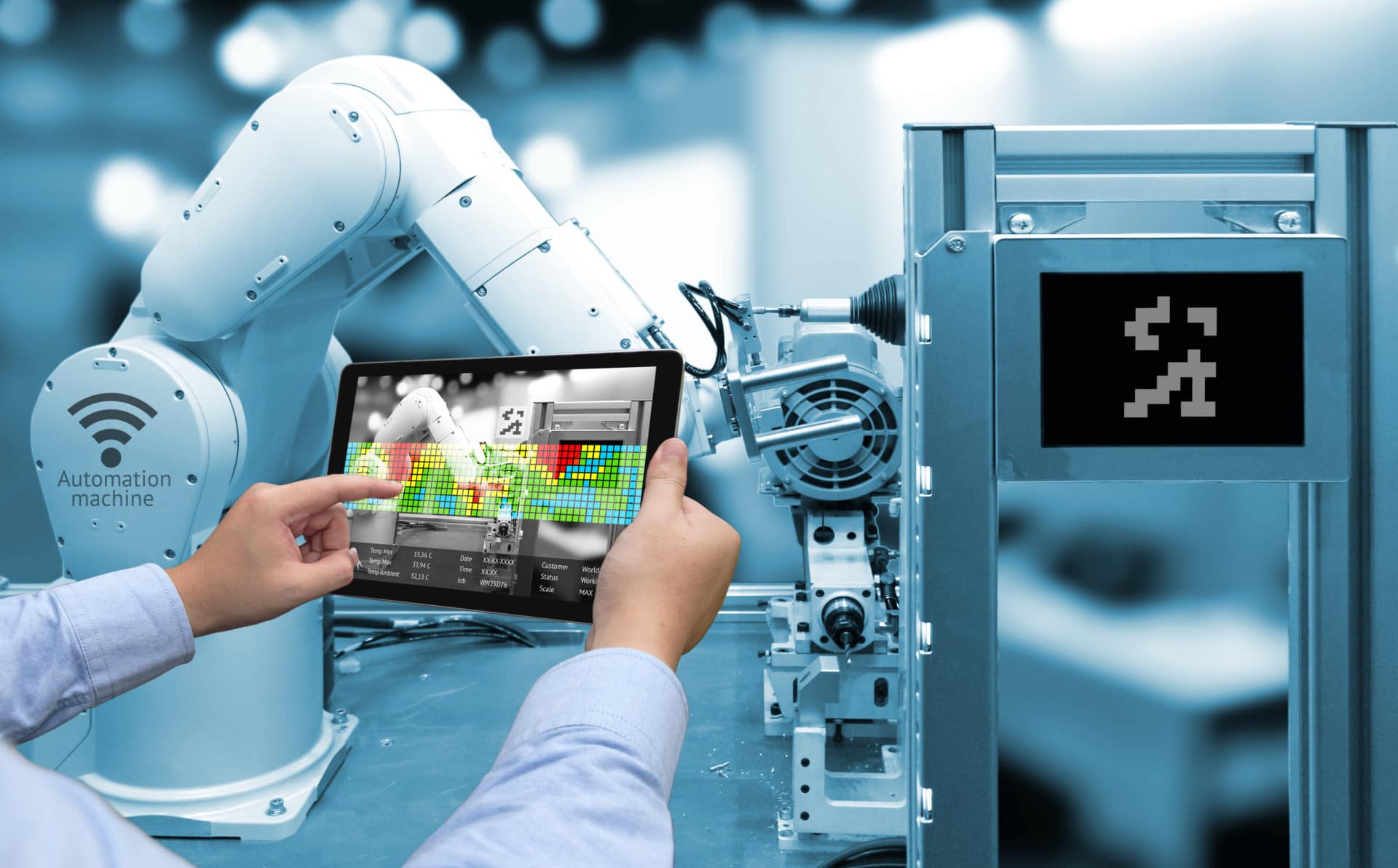

Implementing Data Driven Manufacturing In Northeast Ohio Smart Manufacturing Abstract. the advances in the internet technology, internet of things, cloud computing, big data, and artificial intelligence have profoundly impacted manufacturing. the volume of data collected in manufacturing is growing. big data offers a tremendous opportunity in the transformation of today’s manufacturing paradigm to smart manufacturing. May 28, 2024. at the heart of the fourth industrial revolution (4ir), also known as industry 4.0, smart manufacturing is transforming modern manufacturing operations. the smart manufacturing market, predicted to grow from $223.6 billion to an impressive $985.5 billion by 2032, has led to an increased prevalence of smart factories and smart. Data is the engine: powering a smart manufacturing edge appliance. data is the engine that will drive adoption of industry 4.0, an industrial revolution for automating production and producing better products. yet several factors prevent manufacturers from fully exploiting operational data. traditional operational technology (ot) architectures. Manufacturing is getting smart. companies are increasingly using sensors and wireless technologies to capture data at all stages of a product's life. these range from material properties and the.

The Framework Of Data Driven Smart Manufacturing Download Scientific Diagram Data is the engine: powering a smart manufacturing edge appliance. data is the engine that will drive adoption of industry 4.0, an industrial revolution for automating production and producing better products. yet several factors prevent manufacturers from fully exploiting operational data. traditional operational technology (ot) architectures. Manufacturing is getting smart. companies are increasingly using sensors and wireless technologies to capture data at all stages of a product's life. these range from material properties and the. Smart manufacturing represents the future of industrial production – an automated, data driven revolution poised to enhance customization, quality and efficiency while reducing waste and costs. as this shift toward industry 4.0 gains momentum, it holds vast potential to reshape the manufacturing landscape, tackle global challenges and. The schematic layout of interconnection of smart manufacturing system used in industry4.0 is shown in figure 1.the smart manufacturing system connects the product design, analytics, manufacturing process, stocks and supply chain system, product customization, real time machining units, product delivery system and the end customers through the use of cloud computing which made on demand.

Smart Manufacturing Is The Future 2wtech Smart manufacturing represents the future of industrial production – an automated, data driven revolution poised to enhance customization, quality and efficiency while reducing waste and costs. as this shift toward industry 4.0 gains momentum, it holds vast potential to reshape the manufacturing landscape, tackle global challenges and. The schematic layout of interconnection of smart manufacturing system used in industry4.0 is shown in figure 1.the smart manufacturing system connects the product design, analytics, manufacturing process, stocks and supply chain system, product customization, real time machining units, product delivery system and the end customers through the use of cloud computing which made on demand.

Comments are closed.