Cooling Tower Piping Schematic Diagram

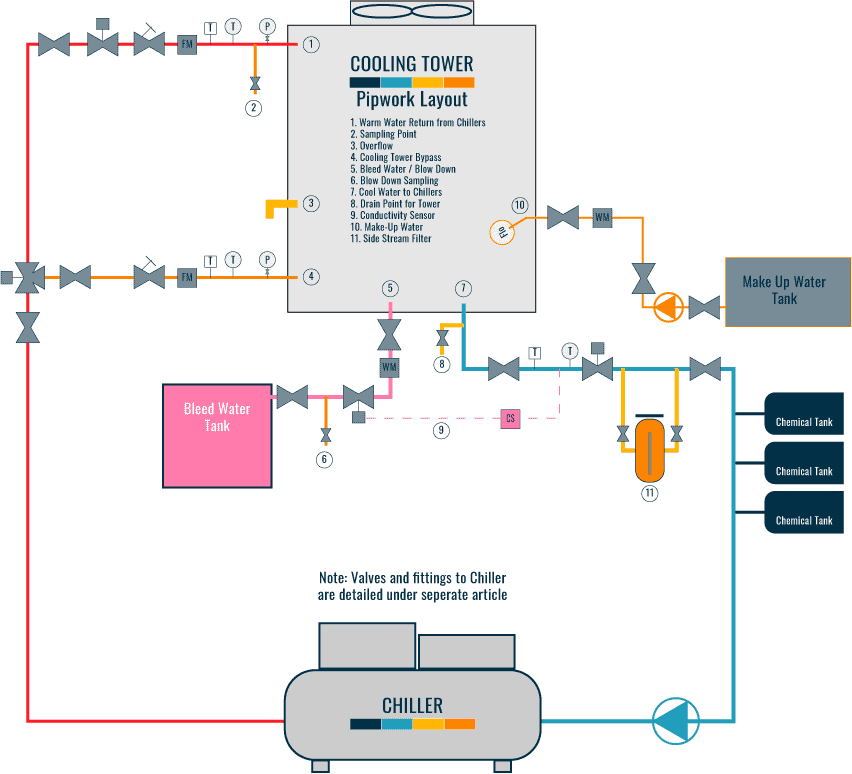

Cooling Tower Piping Layout And Diagrams Constructandcommission Cooling tower | piping layout and diagrams. to allow the cooling towers to operate correctly, in line with the design and efficiently, various systems will need to be connected to allow them to work. depending upon how the towers are installed will mean different configurations would be required. the pipework that is commonly connected to the. Troubles do occur occasionally, however, and these troubles can be classified as caused by: 1. incorrect pump head estimation. 2. pump cavitation and loss of pumping ability, as caused by inadequate pump suction pressure. 3. air in pump suction; as caused by tower pan vortex, pan drain down or faulty bypass. 4.

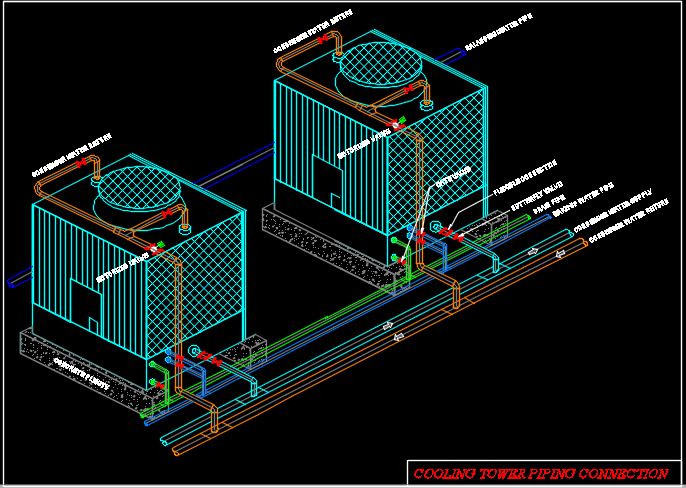

Cooling Tower Piping Schematic Diagram In the design and operation of cooling towers, a piping schematic plays a crucial role in ensuring the efficient and effective cooling of water. this schematic provides a detailed representation of the piping system within a cooling tower, including the flow paths, pipe sizes, valves, and other components. it serves as a roadmap for engineers. The cooling tower piping schematic diagram breaks the cooling tower system into several distinct pieces. first, the piping associated parts are identified. this includes pipes, fittings, valves, pumps, and other instruments which all play an important role in cooling tower operations. the second portion of the diagram identifies the central. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower.

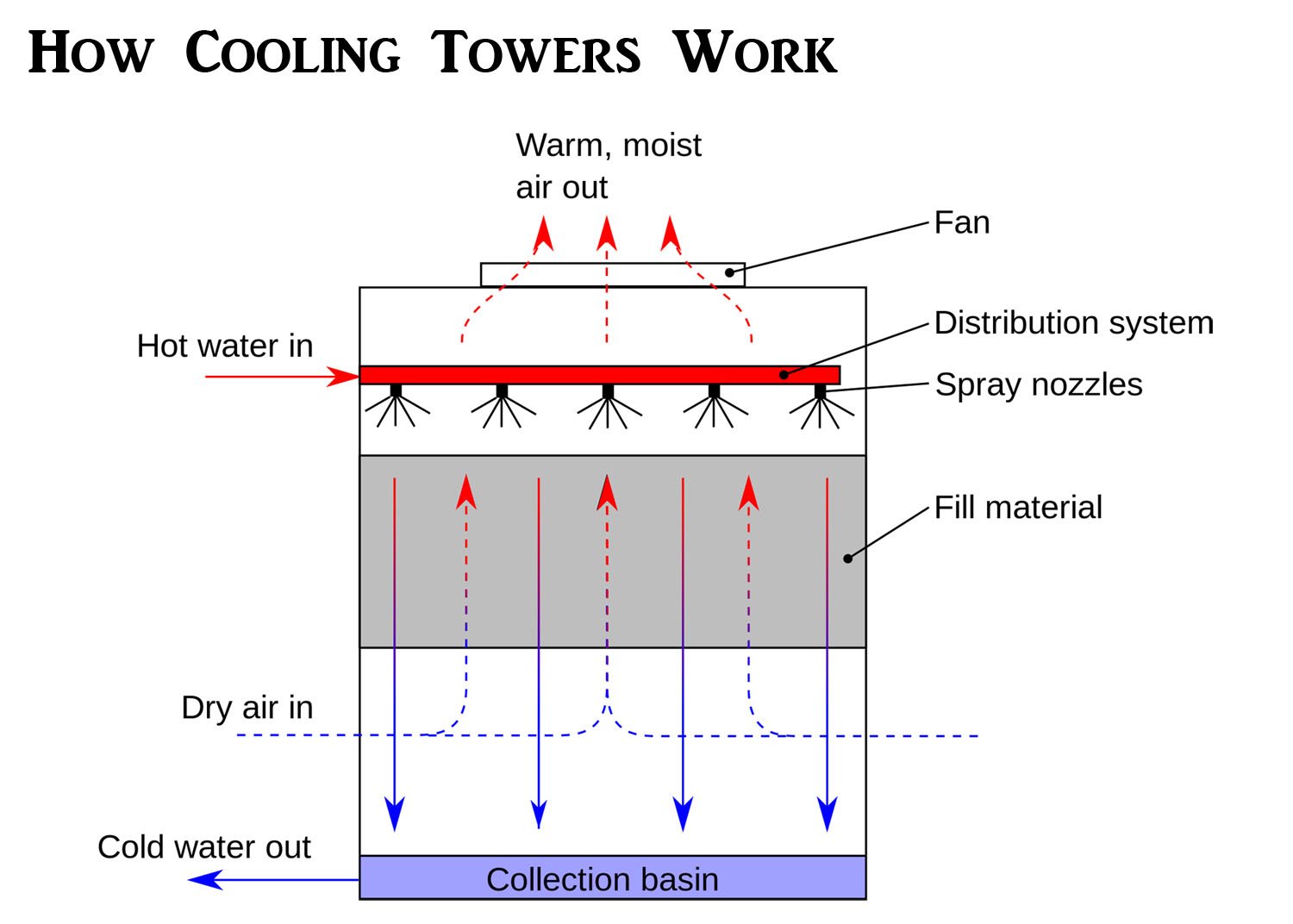

Cooling Tower Piping Schematic Diagram Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower. In a short summary, a cooling tower cools down water that gets over heated by industrial equipment and processes. the hot water is usually caused by air conditioning condensers or other industrial processes. that water is pumped through pipes directly into the cooling tower. Section 1 – evaporative cooling towers an evaporative cooling tower is a heat exchanger that transfers heat from circulating water to the atmosphere. warm water from the heat source is pumped to the top of the tower and then flow down through plastic or wooden shells. as it falls downward . cooling towers – m07 001 3.

Cooling Tower Piping Schematic Diagram In a short summary, a cooling tower cools down water that gets over heated by industrial equipment and processes. the hot water is usually caused by air conditioning condensers or other industrial processes. that water is pumped through pipes directly into the cooling tower. Section 1 – evaporative cooling towers an evaporative cooling tower is a heat exchanger that transfers heat from circulating water to the atmosphere. warm water from the heat source is pumped to the top of the tower and then flow down through plastic or wooden shells. as it falls downward . cooling towers – m07 001 3.

Comments are closed.