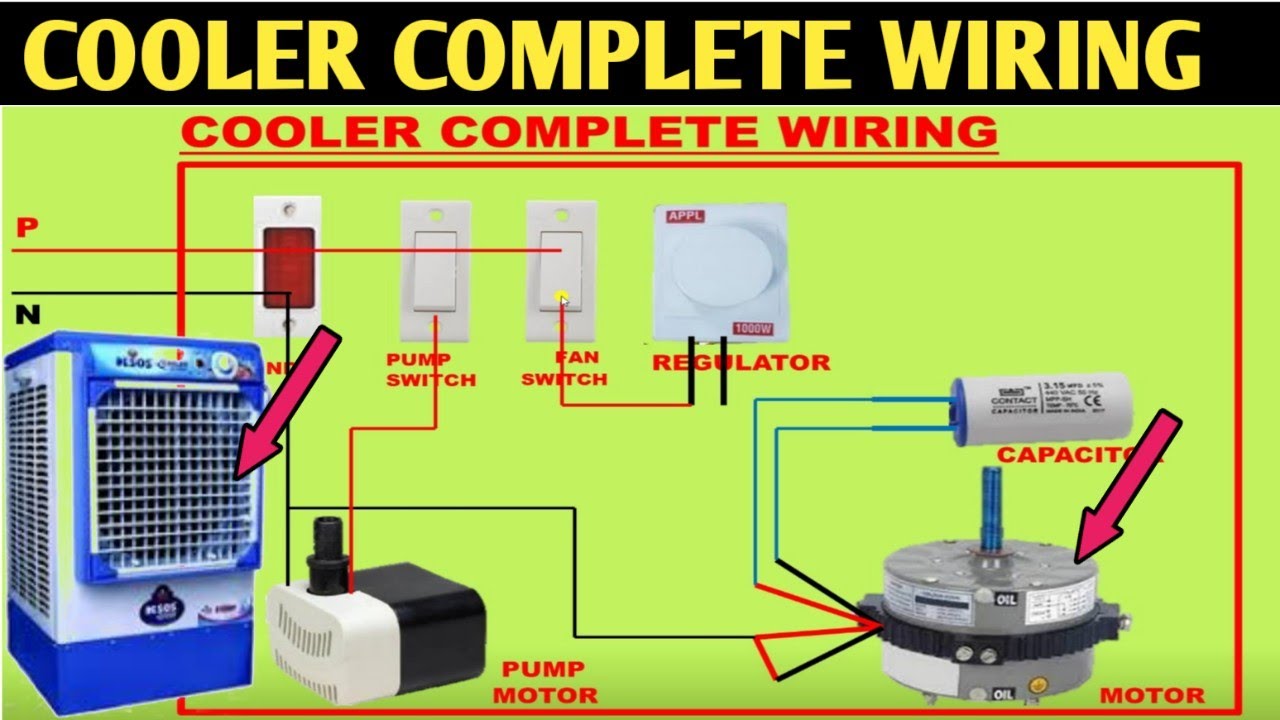

Cooler Connection Diagram With Motor Wiring

4 Wire Cooler Motor Wiring Diagram And Connection Procedure Etec A wiring diagram is a visual representation of the electrical connections and wiring layout of an evaporative cooler motor. this diagram provides a clear guide on how to properly wire and connect the different components of the motor, ensuring efficient and safe operation of the cooler. whether you are a diy enthusiast or a professional, this wiring diagram will help you understand the. Connect the power supply wires to the appropriate terminals on the motor, ensuring a secure connection. connect the fan motor wires to their designated terminals on the motor. connect the pump motor wires to their designated terminals on the motor. if your cooler doesn’t have a pump, skip this step.

Cooler Connection Diagram With Motor Wiring The first step in wiring a 2 speed cooler motor is to gather all the necessary tools and materials. this typically includes wire strippers, electrical tape, wire nuts, and a wiring diagram for your specific motor model. the wiring diagram will provide a visual representation of how the wires should be connected, ensuring that you complete the. "unveil the simplicity of a four wire cooler motor wiring diagram and connections in our informative guide! master the art of connecting and understanding ea. Proper installation and wiring are essential for the optimal functioning of the evaporative cooler. the wiring diagram of an evaporative cooler includes various components that work together to ensure efficient cooling. these components include a motor, pump, thermostat, and junction box. the motor powers the fan, while the pump circulates. Gather the necessary tools and materials. before starting the wiring process, make sure you have all the required tools and materials. this includes a screwdriver, wire strippers, electrical tape, wire nuts, and the evap cooler wiring diagram provided by the manufacturer. 2. turn off the power.

4 Wire Cooler Motor Wiring Diagram And Connection Procedure Etec Proper installation and wiring are essential for the optimal functioning of the evaporative cooler. the wiring diagram of an evaporative cooler includes various components that work together to ensure efficient cooling. these components include a motor, pump, thermostat, and junction box. the motor powers the fan, while the pump circulates. Gather the necessary tools and materials. before starting the wiring process, make sure you have all the required tools and materials. this includes a screwdriver, wire strippers, electrical tape, wire nuts, and the evap cooler wiring diagram provided by the manufacturer. 2. turn off the power. This will help prevent any loose wires or electrical hazards. test the motor: after wiring the motor, it’s important to test it before sealing up the wiring connections. turn on the power to the swamp cooler and switch on the motor. ensure that it operates smoothly and at the desired speed. Make sure to have both flathead and phillips head screwdrivers in different sizes to accommodate different screw types. 2. wire strippers. wire strippers are necessary for removing the insulation from the ends of the wires that will be connected to the motor. this will allow for a solid and secure connection.

Evap Cooler Motor Wiring Diagram This will help prevent any loose wires or electrical hazards. test the motor: after wiring the motor, it’s important to test it before sealing up the wiring connections. turn on the power to the swamp cooler and switch on the motor. ensure that it operates smoothly and at the desired speed. Make sure to have both flathead and phillips head screwdrivers in different sizes to accommodate different screw types. 2. wire strippers. wire strippers are necessary for removing the insulation from the ends of the wires that will be connected to the motor. this will allow for a solid and secure connection.

Comments are closed.