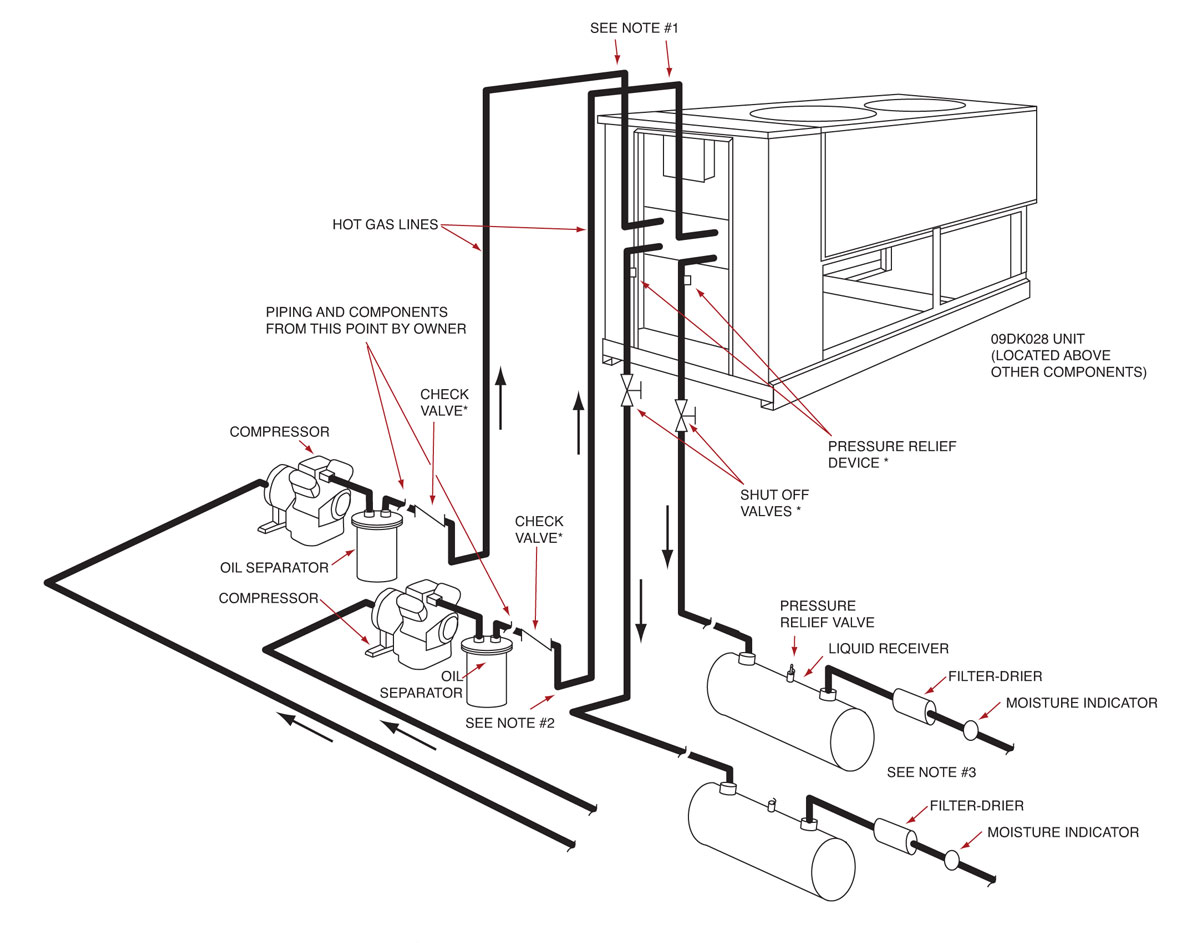

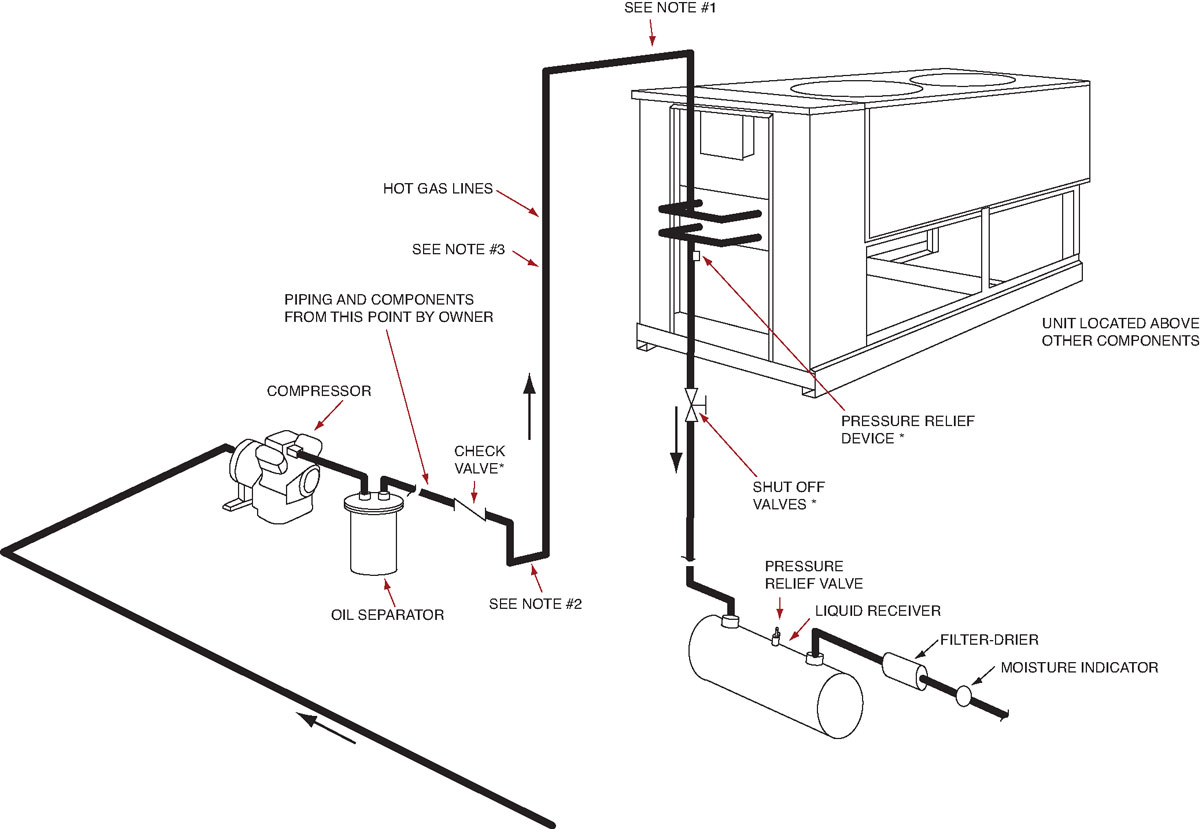

Condenser Piping Diagram

Condenser Piping Diagram This allows the pressure in the receiver to be equalized with the pressure at the coil outlet and thus will allow free liquid flow from the condenser outlet to the receiver. the liquid drain line should also be pitched at least 1 4 inch per foot (20mm per meter) toward the receiver to facilitate this flow. drainage. A condenser water piping diagram is a schematic representation of the layout and components of a condenser water system. it provides a visual guide for designing and constructing the system, as well as for troubleshooting and maintenance purposes. 1. chillers: the chiller is the heart of the condenser water system.

Typical Refrigerant Piping For Outdoor Condenser Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1 2 inch per 10 feet or 1 inch per 20 feet. refrigerant velocities in vertical lines should be at least 1500 ft min to ensure good oil return;. Good piping design results in a balance between the initial cost, pressure drop, and system reliability. the initial cost is impacted by the diameter and layout of the piping. the pressure drop in the piping must be minimized to avoid adversely affecting performance and capacity. because.

Comments are closed.