Closed Circuit Cooling Tower Piping Diagram

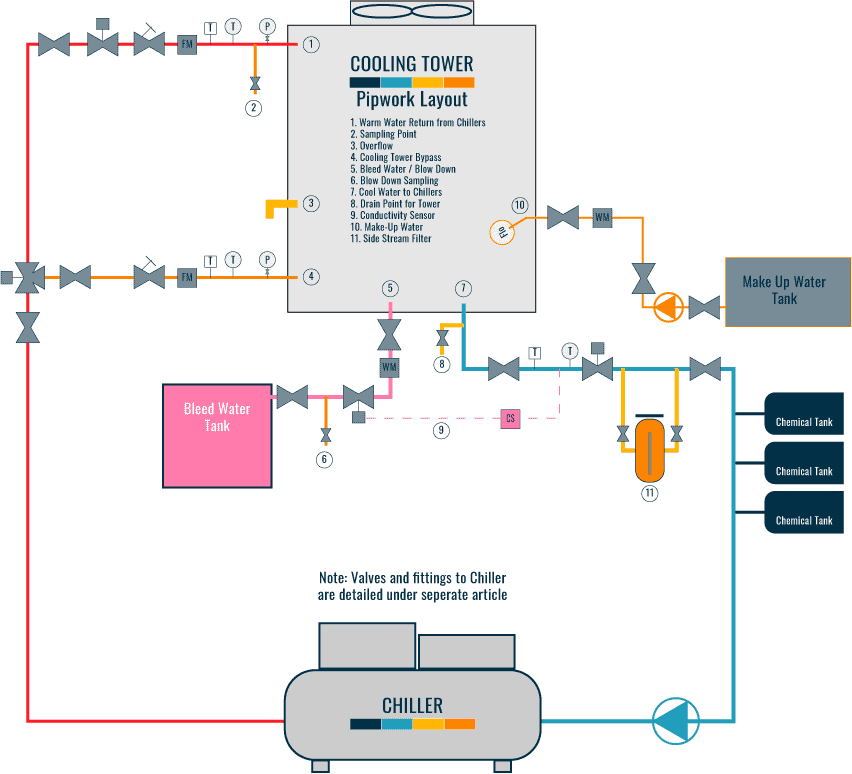

Closed Circuit Cooling Tower Piping Diagram Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system. C sfigure 2 open piping circuitin figure 2, the required pump head will be the pipe flow friction loss from a to d plus the energy head (h s) required to raise wate. from the lower to higher level.the cooling tower circuit differs slightly from the basic “open” circuit in that the discharge piping is connected d.

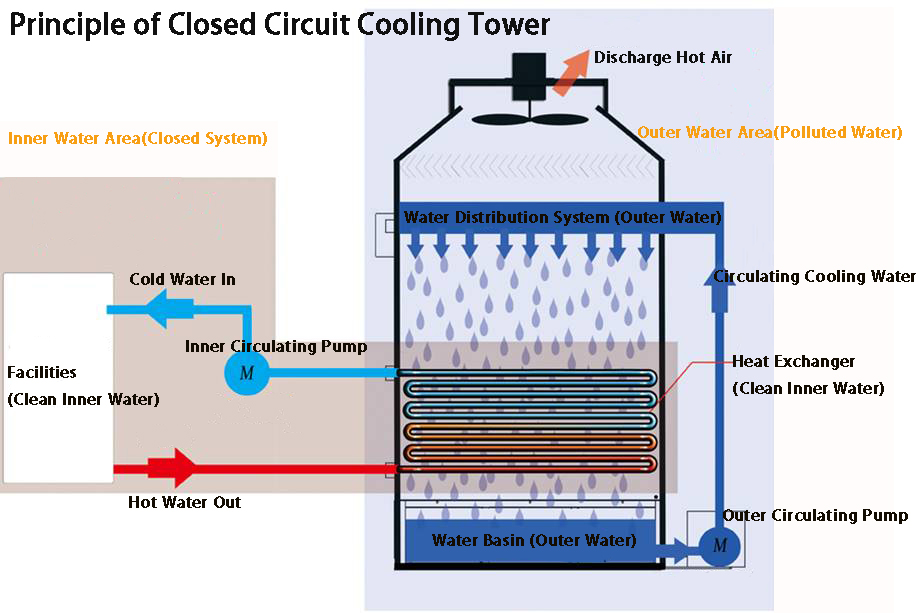

Closed Circuit Cooling Tower Piping Diagram The first step in understanding the complexities of closed circuit cooling tower piping diagrams is to recognize that all of the components must be interconnected in order for the system to function properly. this includes pipes, valves, pumps, tanks and other components. the diagram shows how each of these components connects, as well as the. Cooling tower piping: when designing a cooling tower system for free cooling applications, several piping details should be considered to ensure proper winter operation of the unit. a cooling tower bypass needs to be incorporated into the system design to allow water to “bypass” the tower’s water distribution system as a means of capacity. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

Closed Circuit Cooling Tower Piping Diagram Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil. Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. A closed loop cooling tower piping schematic is a diagram used to illustrate the components and flow of water through a closed loop system. it provides an overview of the entire system, as well as showing the connections between the different components. this type of schematic is particularly useful in cooling applications such as air.

Closed Circuit Cooling Tower Piping Diagram Circuit Diagram Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. A closed loop cooling tower piping schematic is a diagram used to illustrate the components and flow of water through a closed loop system. it provides an overview of the entire system, as well as showing the connections between the different components. this type of schematic is particularly useful in cooling applications such as air.

Comments are closed.